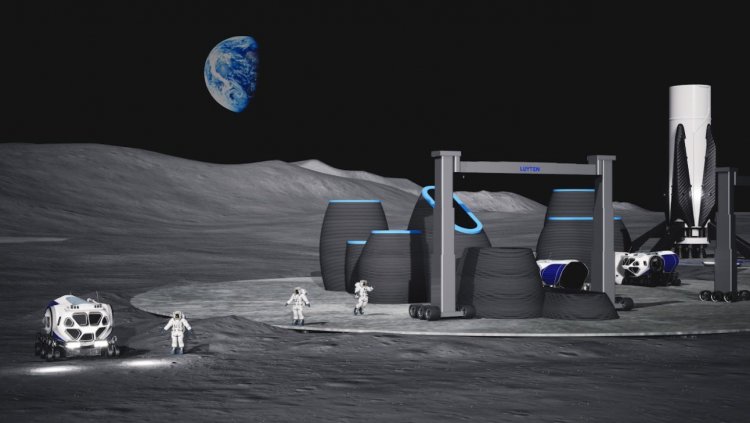

Australian 3D concrete printer technology startup 'Luyten' preparing to build on the moon

SYDNEY, NSW, AUSTRALIA: Australian startup, Luyten, is preparing to build a base camp on the moon using its cutting edge lunar 3D printer.

Since launching in 2020, Luyten’s mission has been to make construction easier and more sustainable across a broad range of industries by reducing the time and cost to build, the amount of construction waste generated, and the impact of build activities on the surrounding environment.

Luyten’s cutting-edge 3D printing and additive technologies have become a world-wide success story as companies across the globe scramble to purchase its printers.

According to cofounder and CEO Ahmed Mahil, Luyten is expanding the scope of its technology use to moon building.

“When we developed our groundbreaking 3D concrete printers, we thought we would be solving building and construction issues across the world – but with discussions currently taking place with people across the space industry we are now looking at solving building and construction issues on the moon,” Mahil said.

“This has led us to commission Project Meeka. Meeka means moon in some of Australia’s First Nations languages.”

Mahil states that in order for humans to fully research and explore the moon, they need to have a lunar base or outpost. Such a base has only existed as a scientific fantasy until recent years. At Luyten, we analysed the concept, compartmentalised it into specific engineering problems and provided an engineering solution making use of scientific advances across multiple disciplines.

“To date, humans have not been able to settle on the moon or transport materials capable of constructing some type of lunar settlement until now. At Luyten we have created a 3D printer light enough to be space worthy so it can be transported to the moon at a reasonable cost and used to build a lunar settlement using lunar materials," Mahil said.

Luyten’s lunar work is advanced and now at a stage where it is fine tuning and testing the type of materials and designs needed for construction purposes on the surface of the moon.

“Through the use of computational methods, three dimensional designs are tested for their structural soundness, including the ability to endure simulated thermal loading experienced on the moon's surface,” Mahil emphasised.

“Once we have finalised the materials required and the designs to be implemented, the construction process will involve a swarm of collaborating robotic printers working with one another and robotic rovers equipped with ground penetrating radar, ultrasonic props, excavation and compacting rollers. These machines will make up the construction team on the moon.

“Transporting the printers from earth to the moon will be a fairly simple process. The 3D printer we have developed to undertake construction on the moon is called Platypus Galacticas.

“This printer is agile and transformable. It can transform from a size of 3m x 4m in height and width to 9m x 12m in height and width, capable of producing a structure of up to 9m x 12m in height and length. The printer can be set up in less than 30 minutes.

“We have designed the printer for compactness using light weight composites for the printer’s structure and robotic transforming technology making it ideal for space transportation purposes.”

Luyten’s architectural designer Brandon Nelson states that Project Meeka’s buildings have been designed based around cylindrical shapes to create a modern safe building to live in.

“These building forms create a unique environment for astronauts to occupy. The profile of the buildings have been parametrically optimised and tested computationally on the physical properties and strength of each form itself. These show an accurate representation of what the building can withstand and how they can protect the astronauts,” Nelson said.

“3D printing construction is going to be the next wave of architecture throughout the world which is going to further architects having more control of projects and how buildings are actually made. 3D printing is going to lead to a whole new architecture model that gives architects a more hands on design/ build approach to architecture.”

The Luyten team also researched the moon surface to identify what type of geotechnical radar will be needed to determine camp base site locations.

“Constructing a lunar settlement is a highly elaborate mission and will require significant technology,” Mahil said.

“First, rovers with ground penetrating radar will assess the location’s structural capacity to build. Meanwhile other rovers with ultrasonic props and excavation capabilities will start harvesting lunar regolith. In order to source building materials from the regolith and then characterise its mechanical properties the excavation rover will deposit collated lunar dust at a regolith sorting reservoir where it will be processed to a finer size. The transforming robots will then initially construct shell structures at the building site.

“After sourcing 3D printable material, the Platypus Galacticas 3D printer will start printing on the compacted lunar surface. The extrudable materials will then be passed through the printing nozzle and form the layers of the structures.”

According to Mahil the moon offers up the ideal materials for 3D printer building.

“Moon regolith will be the primary building material of the printed structures due to its abundance,” Mahil explained.

“Based on the material properties of the specific type of regolith, concentrated microwaves will be used to sinter the regolith into a printable form.”

Mahil points out that space technology benefits the human race every single day.

“A lot of the daily conveniences that people have come to expect, are actually underpinned by space-based technologies. It is easy to forget that things such as internet access, weather forecasting, GPS, online banking and emergency responses to natural disasters all heavily rely on the innovations floating in space above the earth’s surface,” Mahil added.

“We are proud and excited to be recognised for our technology’s space capabilities and compliances. Our team at Luyten is working to single handily remove barriers to construction in hazardous conditions, such as on other planets, by producing reliable technology."